Reusable Bulk Plastic Containers: Longevity and Durability Insights

Wiki Article

Why Bulk Containers Are Important for Enhancing Your Supply Chain and Enhancing Performance

Mass containers play an essential role in maximizing supply chains. Their layout improves storage space efficiency and reduces product packaging waste. Organizations gain from boosted stock management and structured transportation processes. As firms go for cost-effectiveness and sustainability, the adoption of mass containers comes to be increasingly relevant. Nonetheless, the effect of these containers prolongs past simple logistics. Recognizing their wider implications discloses considerable chances for operational renovation. What are the certain benefits that make them important?The Benefits of Bulk Containers in Supply Chain Administration

Although numerous businesses depend on typical product packaging methods, the benefits of bulk containers in supply chain administration are progressively recognized. Bulk containers provide improved performance by making best use of storage area and lowering the regularity of shipments. Their standardized dimensions promote less complicated handling and transport, resulting in streamlined logistics processes. Furthermore, these containers give superior security for products, decreasing the risk of damage throughout transportation. By making use of bulk containers, companies can additionally improve inventory administration, as they enable better tracking and control of stock degrees. In addition, using bulk containers can cause raised operational flexibility, allowing services to adjust to adjustments popular better. Generally, mass containers stand for a calculated advantage in modern-day supply chain techniques.Price Financial Savings With Minimized Product Packaging and Waste

Mass containers substantially add to set you back savings by reducing packaging materials and minimizing waste. By using mass containers, companies can considerably reduce the amount of product packaging needed for carrying products, which leads to decrease product expenses. Additionally, this decrease in packaging not only minimizes costs yet likewise diminishes the environmental impact related to waste disposal - Industrial Bulk Plastic Containers. With less materials to take care of, firms can improve their procedures, improving general operational effectiveness. The space-saving design of mass containers likewise enables enhanced transport logistics, additionally adding to minimized shipping costs. Ultimately, embracing mass containers promotes a more lasting and economical technique to supply chain administration, making it possible for organizations to designate resources better and enhance their profits

Enhanced Supply Management With Bulk Storage Space Solutions

Bulk storage options use significant benefits for supply monitoring by optimizing room application and simplifying stock monitoring processes. By combining supply into fewer, bigger containers, companies can take full advantage of storage space capability while reducing clutter. This improved organization not only simplifies keeping an eye on supply degrees yet also helps with even more precise projecting and replenishment.Boosted Space Utilization

When organizations implement bulk storage options, they often experience significant improvements in space application, which straight enhances inventory monitoring. By combining products into mass containers, firms take full advantage of horizontal and vertical storage space capability, reducing squandered area. This effective arrangement not just enables for even more supply to be kept within the same impact but also promotes easier access to products. The decrease of aisle room typically needed for smaller sized containers additionally optimizes storehouse designs. In addition, mass storage space solutions can accommodate a range of item shapes and sizes, making it less complicated to adapt to altering stock needs. Consequently, companies can accomplish an extra well organized and effective storage facility environment, inevitably causing improved functional performance and decreased overhanging expenses.Simplified Supply Monitoring

Improved Transportation Performance and Handling

As companies seek to enhance their logistics operations, the fostering of mass containers becomes an essential strategy for improving transportation performance and handling procedures. These containers promote the movement of big amounts of products, lowering the variety of trips needed and ultimately lowering transportation costs. Their uniform shapes and size enable enhanced loading and dumping, decreasing wait times at ports and stockrooms. Additionally, bulk containers streamline dealing with by allowing using specific tools, such as forklifts and automated systems, which enhance speed and decrease labor costs. By consolidating items right into less shipments, business can likewise boost supply monitoring and reduce the danger of damages, inevitably bring about an extra effective supply chain on the whole.Environmental Advantages of Making Use Of Mass Containers

Using bulk containers substantially adds to ecological sustainability within the supply chain. By minimizing packaging waste and advertising sustainable material usage, these containers aid reduced the total carbon impact connected with transportation and storage space. This change in the direction of bulk options straightens with international initiatives to reduce environmental impact and enhance source effectiveness.

Reduced Product Packaging Waste

Bulk containers significantly add to lowered product packaging waste, providing an engaging benefit for services and the setting alike. By making use of bulk containers, companies can reduce the amount of material required to package products, leading to less overall waste. Traditional product packaging usually entails numerous layers of products, which can be both environmentally harmful and costly. In contrast, bulk containers settle items into less systems, lowering the demand for extreme wrapping, boxes, or containers. This improving not only decreases disposal prices however additionally streamlines recycling efforts. Furthermore, using long lasting, multiple-use mass containers permits companies to embrace a more lasting technique, fostering a culture of ecological responsibility. Inevitably, the change to bulk containers sustains both operational efficiency and eco-friendly conservation.Reduced Carbon Footprint

A substantial decrease in carbon footprint is just one of the essential ecological advantages connected with making use of mass containers. These containers minimize the requirement for extreme packaging materials, which often add to waste and greenhouse gas exhausts during manufacturing and disposal. By carrying items in larger amounts, mass containers decrease the variety of journeys called for, bring about lower gas consumption in logistics. This reliable transport method not just minimizes carbon discharges yet likewise maximizes supply chain operations. Additionally, the resilience of bulk containers warranties they can be reused several times, furthermore lowering the ecological impact compared to single-use packaging. Overall, the adoption of bulk containers plays an essential function in promoting a much more lasting supply chain.

Lasting Product Use

While helping sustainability, firms progressively transform to mass containers that utilize eco-friendly materials. These containers, usually made from recycled or biodegradable substances, significantly minimize ecological influence contrasted to standard product packaging. By decreasing dependence on single-use plastics, bulk containers add to waste reduction and advertise a round economy. Their long lasting style enables for multiple usages, enhancing resource efficiency. Firms taking on these environment-friendly remedies can also boost their brand image, interesting eco conscious customers. Furthermore, using lasting materials in bulk containers often causes More hints lower power consumption throughout production, aligning with company sustainability goals. Generally, the shift towards lasting material use in mass containers is a crucial action in cultivating a much more responsible supply chainCase Studies: Successful Integration of Bulk Containers in Various Industries

Countless markets have effectively incorporated bulk containers right into their supply chain operations, boosting performance and lowering costs. For instance, the food and beverage field has actually utilized mass containers to streamline component storage space and transport, reducing waste and boosting inventory administration. In the chemical sector, companies have actually adopted bulk containers to assist in more secure handling and storage of harmful materials, thus raising conformity with safety guidelines. Additionally, the automobile market has actually applied mass containers for the transportation of parts, minimizing product packaging waste and boosting production line effectiveness. These study highlight how bulk containers can not only enhance logistics yet also advertise sustainability throughout numerous fields, eventually leading to much better resource monitoring and raised profitability.Frequently Asked Questions

What Kinds of Materials Are Generally Kept wholesale Containers?

Generally, bulk containers keep materials such as grains, chemicals, steels, aggregates, and liquids. Bulk Plastic Containers. These containers accommodate different sectors, promoting the reliable transportation and storage of big quantities of materials, ensuring structured handling and minimized wasteJust How Do Mass Containers Affect Item Quality Throughout Transportation?

Bulk containers secure items from ecological variables, reduce contamination dangers, and reduce activity during transportation. Their robust building warranties stability, maintaining product integrity and top quality throughout the supply chain, ultimately bring about improved customer complete satisfaction.

What Are the Common Dimensions of Bulk Containers Available?

Usual dimensions of mass containers generally consist of 40-foot and 20-foot containers, with capacities ranging from 1,000 to 2,700 litres for intermediate bulk containers, accommodating different products for reliable transport and storage space solutions.Can Bulk Containers Be Personalized for Specific Products?

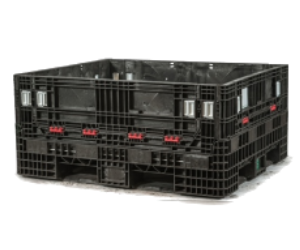

Yes, bulk containers can be personalized for specific products. Different products, sizes, and layouts are offered to fulfill unique see here needs, making sure perfect security and performance during storage and transport of diverse products.Exactly how Do I Pick the Right Bulk Container for My Requirements?

To pick the right bulk container, one must consider item features, weight capacity, material compatibility, and designated transport technique. Furthermore, reviewing storage space and regulatory requirements will additionally assure the option fulfills details needs efficiently.Bulk containers provide improved effectiveness by taking full advantage of storage room and lowering the regularity of deliveries. Bulk containers substantially add to set you back financial savings by decreasing product packaging products and lowering waste. In comparison, mass containers combine products informative post into fewer units, reducing the need for extreme covering, boxes, or containers. Many industries have actually effectively incorporated bulk containers into their supply chain operations, boosting efficiency and reducing prices. In addition, the vehicle industry has executed bulk containers for the transport of components, lowering packaging waste and boosting assembly line efficiency.

Report this wiki page